So i recently bought a water pump and a 3" Keene power jet and it kinda works. The setup won't pick up rocks any bigger than 1" and I'd like a little more power than that without having to buy a new pump. So I did a little research on the web and I read this article here:

http://www.gouldeng.com/gettingbestper.htm

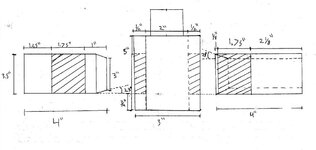

What I can gather from the article, the infinity jet is a nozzle that shoots water in from all 360 degrees around the pipe rather than from one location like with a standard power jet. He's saying the infinity jet is almost 3 times as efficient as a standard power jet, do you think this is true? Also what do you think would be the best angle for the water to leave the nozzle at?

Thanks,

http://www.gouldeng.com/gettingbestper.htm

What I can gather from the article, the infinity jet is a nozzle that shoots water in from all 360 degrees around the pipe rather than from one location like with a standard power jet. He's saying the infinity jet is almost 3 times as efficient as a standard power jet, do you think this is true? Also what do you think would be the best angle for the water to leave the nozzle at?

Thanks,

For the best induction angle check your taper to see if between 11-13 degrees too for a bit more efficent push also. John

For the best induction angle check your taper to see if between 11-13 degrees too for a bit more efficent push also. John John

John