Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

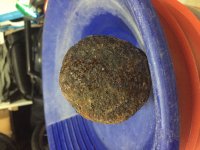

What is this?

- Thread starter kikinit247

- Start date

bowwinkles

Bronze Member

- Nov 3, 2012

- 2,105

- 2,493

- Primary Interest:

- All Treasure Hunting

vintage rock hammer

Duckshot

Silver Member

- Sep 8, 2014

- 4,455

- 9,643

- Primary Interest:

- All Treasure Hunting

Stupid carpenter (me) says it might be a candle holder.

It gets hammered into the shaft or tunnel wall, candle goes in hole. To me that hole looks too small for a hamer's handle. What are the dimensions?

It gets hammered into the shaft or tunnel wall, candle goes in hole. To me that hole looks too small for a hamer's handle. What are the dimensions?

Last edited:

N-Lionberger

Bronze Member

- Dec 1, 2013

- 1,419

- 2,061

- Detector(s) used

- Fisher 1212-x

Fisher Gold Bug 2

Whites 4900/SP3

Dowsing rods

- Primary Interest:

- Prospecting

is that a point or a wedge shape? Judging by the mushrooming on the hammer head it makes me think if its a wedge shape it might have been used for trimming rail ends, if its just a point it might have been part of a blacksmiths kit or indeed a rock hammer but the mushrooming makes me think it was used for somthing else. Thats way too fat to be a sticking tommy candle holder all of the ones in my collection are +-1/4" diameter in the part you drive into a timber or crack in the rock.

Last edited:

arizau

Silver Member

- May 2, 2014

- 2,518

- 3,947

- Detector(s) used

- Beach High Banker, Sweep Jig, Whippet Dry Washer, Lobo ST, 1/2 width 2 tray Gold Cube, numerous pans, rocker box, and home made fluid bed and stream sluices.

- Primary Interest:

- Prospecting

What ever it is it will be of more value, as is, to an antique collector so don't take the rust off in case you seek to sell it.

Last edited:

Duckshot

Silver Member

- Sep 8, 2014

- 4,455

- 9,643

- Primary Interest:

- All Treasure Hunting

Ah-ha!

Good explanation Gambrinus.

Good explanation Gambrinus.

kikinit247

Jr. Member

- Thread starter

- #9

bowwinkles

Bronze Member

- Nov 3, 2012

- 2,105

- 2,493

- Primary Interest:

- All Treasure Hunting

Its style/size and its location where it was recovered still leads me to view it as being a rock hammer.

Goldwasher

Gold Member

- May 26, 2009

- 6,083

- 13,244

- 🥇 Banner finds

- 1

- Detector(s) used

- SDC2300, Gold Bug 2 Burlap, fish oil, .35 gallons of water per minute.

- Primary Interest:

- All Treasure Hunting

not necessarily trueWhat ever it is it will be of more value, as is, to an antique collector so don't take the rust off in case you seek to sell it.

I'm a member of a few Ca. mining relic groups.

Guys clean off the outer rusty scale of of many different items. using several methods.

The tools look much better and the rot is stopped

its pretty cool how many of them turn out.

N-Lionberger

Bronze Member

- Dec 1, 2013

- 1,419

- 2,061

- Detector(s) used

- Fisher 1212-x

Fisher Gold Bug 2

Whites 4900/SP3

Dowsing rods

- Primary Interest:

- Prospecting

Its style/size and its location where it was recovered still leads me to view it as being a rock hammer.

A lot of mines had a blacksmith shop on site for repairing/building equipment, sharpenening drills etc... The mushrooming of the head indicates it was being hammered on. Hammer heads don't typically mushroom like that.

bowwinkles

Bronze Member

- Nov 3, 2012

- 2,105

- 2,493

- Primary Interest:

- All Treasure Hunting

A lot of mines had a blacksmith shop on site for repairing/building equipment, sharpenening drills etc... The mushrooming of the head indicates it was being hammered on. Hammer heads don't typically mushroom like that.

You may be correct but hammers that are used on uneven surfaces like stone tend to mushroom. The one plus in your favor is the small diameter of the hole for the handle tends to support your thoughts. a rock hammer would have a much larger hole and the mass of the handle should be bigger also. That still does not say that some may also use it for a rock hammer. I have been known to drive a nail with a bald peen

Goldwasher

Gold Member

- May 26, 2009

- 6,083

- 13,244

- 🥇 Banner finds

- 1

- Detector(s) used

- SDC2300, Gold Bug 2 Burlap, fish oil, .35 gallons of water per minute.

- Primary Interest:

- All Treasure Hunting

You may be correct but hammers that are used on uneven surfaces like stone tend to mushroom. The one plus in your favor is the small diameter of the hole for the handle tends to support your thoughts. a rock hammer would have a much larger hole and the mass of the handle should be bigger also. That still does not say that some may also use it for a rock hammer. I have been known to drive a nail with a bald peen

miners did repurpose broken pick, axe and hammer heads as wedges to break rock apart.

Though if it was being used on rock I would expect both ends to show wear

It's a "round punch" blacksmith hammer missing the wooden handle. That type of hammer is not swung you use another hammer to hit the punch,

the handle is there so you can hold the punch steady.

View attachment 1637829

You got me convinced. Judging by the similar ones on e-bay that all have a very slim profile where the handle enters the head is pretty much a no brainer. Being a carpenter, wood cutter, mechanic kinda guy I have no hammers that have such a small profile....it would simply break in a very short period of time. I also suspect that the hammers head is mushroomed because most blacksmiths would use a very, very hard metal on their "hammers" used for pounding and the punchs' metal is probably softer metal. check these out... ( https://www.ebay.com/sch/i.html?_nk...c=1&_salic=1&_sop=12&_dmd=1&_ipg=100&_fosrp=1 )

As an eBay Associate we earn from qualifying purchases.

N-Lionberger

Bronze Member

- Dec 1, 2013

- 1,419

- 2,061

- Detector(s) used

- Fisher 1212-x

Fisher Gold Bug 2

Whites 4900/SP3

Dowsing rods

- Primary Interest:

- Prospecting

The handle doesnt need to be super stout as it is there just to hold the punch over the work, if you tried holding a conventional punch you would burn the crap out of yourself over that orange hot metal.

gold tramp

Bronze Member

- Dec 30, 2012

- 1,387

- 2,893

- Primary Interest:

- Other

The handle doesnt need to be super stout as it is there just to hold the punch over the work, if you tried holding a conventional punch you would burn the crap out of yourself over that orange hot metal.

Yes and always remember the end of that steel looks cold sticking out of the forge.

It's very hot also !!!!

Gt.....

Top Member Reactions

-

3544

3544 -

2091

2091 -

2032

2032 -

1199

1199 -

1101

1101 -

923

923 -

850

850 -

828

828 -

809

809 -

777

777 -

771

771 -

548

548 -

531

531 -

458

458 -

455

455 -

450

450 -

E

422

-

416

416 -

415

415 -

404

404

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)