I doubt this is a new idea, nor is it an earth-shattering discovery, but I have found this solution to be helpful and a little more efficient.

Since I have been prospecting for a while, I usually prospect in one of four ways:

1. Test Panning - Research new streams on maps, get permission, and then take shovel and pan and test/evaluate a new stream to see if it has any gold - Equipment - shovel, pan

2. Five Gallon Test - If the test panning produces results, I return to the best (most productive) test pan site and run a few buckets of classified material through a lightweight sluice-box to see if the stream has more than just a little flood gold.

3. Long-Day Sluicing - If the five gallon test produces decent gold, I come back with a more robust sluice-box and spend a day - run 100-150 gallons of material through the sluice-box. I also confirm that there are multiple dig sites that also are likely to have good gold

4. Dredge - After getting written permission to dredge (if I can), I bring in a 4" dredge and usually spend several months of weekends, dredging and sending in my gold for cash

This idea is to make the five-gallon test process go easier:

1. I prefer to classify all my material before running it through a sluice

2. Most classifiers are screens inside of a plastic round frame - where the bottom 3"-4" of the classifier fits into the top of your everyday 5-gallon bucket.

3. I find it to be a pain to be constantly rinsing material, stopping, shaking the classifier, and I inevitably knock the bucket over and/or knock the classifier off the top of the bucket several times and generally get annoyed.

4. Yes, I can use a tub with a screen over the top or other methods, but for simple/quick bucket classifying it is not ideal

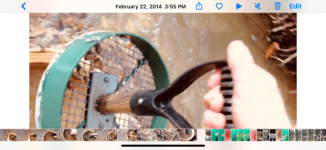

5. So I have build an insert screen, with a handle that fits all the way into the five gallon bucket. Here is basically all you need:

Five gallon bucket

A shovel handle dowel with a sturdy handle - I just buy the cheap 36 inch small shovels at Home Depot that have a short dowel with a nice snow shovel handle on the end and just cut off the shovel blade

A piece of relatively thin metal sheeting with holes in it. I have found metal kitchen colander or certain types of grill plates - with 1/4 inch holes already drilled into them to be the best also pretty cheap to get at Home Depot

One 2" lag bolt

One larger washer with an outside diameter of the wooden shovel dowel and an inside hole that fits snugly over the lag bolt

How to build your insert:

Cut the sheet metal, grill plate, or colander grating with holes already in it - or drill out bigger ones if you want to - into a circular shape, approximately 1.5"-2" wider in diameter than the diameter of the inside of a 5-gallon bucket

Make 4-6, 1/5"-2" cuts into the circular piece of sheet metal - this is to make it really easy to bend up the edges of the metal sheet to create a lip to hold the unclassified tailings/rocks

Use a vice or vice-grip pliers to fold the sheet metal (upward and all in the same direction) so you end up with basically a metal, flat-bottomed bowl, with holes throughout, and 1.5"-2" sides (also with holes in it)

Fold/Bend/Shape the flat bottomed 'bowl' until it fits snugly into the 5-gallon bucket. It should be a snug fit, but it should easily fit all the way into the 5-gallon bucket and can rest on the bottom of the bucket

Drill a hole (or use one already there if it is in the center) into the center of the metal 'bowl' so your lag bolt will fit through the hole

Cut your shovel dowel so that it is a few inches higher than the height of the five gallon bucket

Place the washer onto the lag bolt first, then place the metal 'bowl' (with the top of the folded bowl- lip facing toward the shovel handle. on top of the larger washer

Screw the lag-bolt into the bottom of the dowel (I use a drill and make a hole smaller than the threads of the lag bolt to make sure the lag-bolt goes in straight and to make it easier to screw in all the way), until the metal bowl is firmly attached to the dowel - the metal bowl should not wobble and you should not be able to spin it at all.

How to use your insert:

At your dig-site, fill you 5-gallon bucket with water

Find or make a level place to rest the full bucket, so you can reach it easily and so you can shovel material into it it easily

Place the metal bowl onto the bottom of the bucket full of water

Shovel in your material - use 3-4 shovel fulls but not too many - or the bowl gets too heavy/stuck on the bottom of the bucket.

Pull up on the shovel handle and use the water in the bucket to wash/classify material.

When it is all washed through, pull the bowl out of the bucket and just tilt it sideways to dump the tailings/rocks

Rinse/Repeat

I have found this approach to be about twice as efficient, it is easier on my back since I only need to reach down to the shovel handle, I rarely knock over the bucket since it is full of water, and I never have to deal with knocking the classifier off the top of the bucket.

If you decide to give this a try, I hope you will find it to be as helpful as I have.

Reply With QuoteReply With Quote

Since I have been prospecting for a while, I usually prospect in one of four ways:

1. Test Panning - Research new streams on maps, get permission, and then take shovel and pan and test/evaluate a new stream to see if it has any gold - Equipment - shovel, pan

2. Five Gallon Test - If the test panning produces results, I return to the best (most productive) test pan site and run a few buckets of classified material through a lightweight sluice-box to see if the stream has more than just a little flood gold.

3. Long-Day Sluicing - If the five gallon test produces decent gold, I come back with a more robust sluice-box and spend a day - run 100-150 gallons of material through the sluice-box. I also confirm that there are multiple dig sites that also are likely to have good gold

4. Dredge - After getting written permission to dredge (if I can), I bring in a 4" dredge and usually spend several months of weekends, dredging and sending in my gold for cash

This idea is to make the five-gallon test process go easier:

1. I prefer to classify all my material before running it through a sluice

2. Most classifiers are screens inside of a plastic round frame - where the bottom 3"-4" of the classifier fits into the top of your everyday 5-gallon bucket.

3. I find it to be a pain to be constantly rinsing material, stopping, shaking the classifier, and I inevitably knock the bucket over and/or knock the classifier off the top of the bucket several times and generally get annoyed.

4. Yes, I can use a tub with a screen over the top or other methods, but for simple/quick bucket classifying it is not ideal

5. So I have build an insert screen, with a handle that fits all the way into the five gallon bucket. Here is basically all you need:

Five gallon bucket

A shovel handle dowel with a sturdy handle - I just buy the cheap 36 inch small shovels at Home Depot that have a short dowel with a nice snow shovel handle on the end and just cut off the shovel blade

A piece of relatively thin metal sheeting with holes in it. I have found metal kitchen colander or certain types of grill plates - with 1/4 inch holes already drilled into them to be the best also pretty cheap to get at Home Depot

One 2" lag bolt

One larger washer with an outside diameter of the wooden shovel dowel and an inside hole that fits snugly over the lag bolt

How to build your insert:

Cut the sheet metal, grill plate, or colander grating with holes already in it - or drill out bigger ones if you want to - into a circular shape, approximately 1.5"-2" wider in diameter than the diameter of the inside of a 5-gallon bucket

Make 4-6, 1/5"-2" cuts into the circular piece of sheet metal - this is to make it really easy to bend up the edges of the metal sheet to create a lip to hold the unclassified tailings/rocks

Use a vice or vice-grip pliers to fold the sheet metal (upward and all in the same direction) so you end up with basically a metal, flat-bottomed bowl, with holes throughout, and 1.5"-2" sides (also with holes in it)

Fold/Bend/Shape the flat bottomed 'bowl' until it fits snugly into the 5-gallon bucket. It should be a snug fit, but it should easily fit all the way into the 5-gallon bucket and can rest on the bottom of the bucket

Drill a hole (or use one already there if it is in the center) into the center of the metal 'bowl' so your lag bolt will fit through the hole

Cut your shovel dowel so that it is a few inches higher than the height of the five gallon bucket

Place the washer onto the lag bolt first, then place the metal 'bowl' (with the top of the folded bowl- lip facing toward the shovel handle. on top of the larger washer

Screw the lag-bolt into the bottom of the dowel (I use a drill and make a hole smaller than the threads of the lag bolt to make sure the lag-bolt goes in straight and to make it easier to screw in all the way), until the metal bowl is firmly attached to the dowel - the metal bowl should not wobble and you should not be able to spin it at all.

How to use your insert:

At your dig-site, fill you 5-gallon bucket with water

Find or make a level place to rest the full bucket, so you can reach it easily and so you can shovel material into it it easily

Place the metal bowl onto the bottom of the bucket full of water

Shovel in your material - use 3-4 shovel fulls but not too many - or the bowl gets too heavy/stuck on the bottom of the bucket.

Pull up on the shovel handle and use the water in the bucket to wash/classify material.

When it is all washed through, pull the bowl out of the bucket and just tilt it sideways to dump the tailings/rocks

Rinse/Repeat

I have found this approach to be about twice as efficient, it is easier on my back since I only need to reach down to the shovel handle, I rarely knock over the bucket since it is full of water, and I never have to deal with knocking the classifier off the top of the bucket.

If you decide to give this a try, I hope you will find it to be as helpful as I have.

Reply With QuoteReply With Quote

Amazon Forum Fav 👍

Upvote

0