Jim Hemmingway

Hero Member

- Jan 26, 2008

- 791

- 1,624

- Detector(s) used

- F-75, Infinium LS, MXT, GoldBug2, TDI Pro, 1280X Aquanaut, Garrett ProPointer

- Primary Interest:

- Prospecting

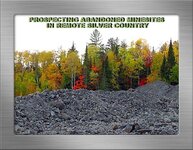

The White’s TDI Pro in Northeastern Ontario Silver Country

A Revised Edition April, 2015

Introduction

The TDI Pro is a manual ground balance pulse induction unit primarily designed as a gold detector. It has proved effective for other pursuits such as relic, beach and even coin hunting to some limited extent. Searching for silver nuggets and ores here in northeastern Ontario’s silverfields with the TDI Pro is a rather unique and intriguing application of this detector. This report looks closely at the Pro’s detection capabilities in a tough prospecting environment, where hobbyists must deal with difficult ferromagnetic mineralizations, abundant ferrous trash, and both non-conductive and electrically conductive positive hotrocks. The unit possesses features that permit it to effectively separate some iron trash from silver, and the subject of its iron-handling ability is discussed in detail later in the report.

Naturally some comparisons are made to the Garrett Infinium LS and these are included here because hobbyists want responsible comparison information. Many would like to understand how these units compare with respect to iron identification or elimination, and depth capabilities. Of course there are conditions where their individual feature sets permit one unit to excel over the other, but that is to be expected. The TDI Pro is a versatile instrument that proved effective at finding some beautiful silver in highly ferromagnetic mineralized substrates where VLF prospecting-capable units struggle for depth and sensitivity.

A Quickview of the TDI Pro Controls and Features

TDI Pro is a solidly constructed unit with user-friendly analogue controls. It is lightweight, better balanced and less fatiguing to use compared to many PI units. Over the normal course of detecting where it is frequently set aside to dig targets, no undue arm fatigue was experienced. The TDI Pro can be hip / chest mounted to further reduce weight.

The Pro comes with two lithium battery packs, a seven hour AC charger, and a “fast charge” three hour full charge auto cigarette lighter plug-in type charger. When the battery dies and needs recharging, the bright battery warning indicator light turns completely off in about a half-minute. With a full charge the TDI Pro is good for another full day of detecting, or approximately eight (8) hours continuous use.

Gain determines the depth /sens that the detector sees a target at any given combination of ground balance and pulse delay settings. Optimal sensitivity is typically in the 6-8 range in tough ground but can be operated at higher levels at many locations. The gain setting affects the unit’s susceptibility to ground minerals and electromagnetic interference (EMI). Excessive gain may increase instability resulting in excessive chatter and false signals. Set it for the prevailing conditions such that the threshold is reasonably smooth, permitting you to easily hear and identify target signals. The frequency control can mitigate EMI to some extent, allowing operation near or under power lines.

Threshold control is best set above the “chatter” level to obtain a consistent “mosquito-like” hum. Reducing the threshold below the chatter zone to “silent” threshold reduces depth / sens especially to smaller or fringe depth targets. If the threshold volume level is excessive, adjust the volume control to reduce it. If using headphones, one may set the volume control to maximum and then adjust the headphone volume level to your preference.

Target Conductivity (Tone Mode) Toggle is activated when the GB Fine control is turned ON. It permits the user to choose whether signals are heard from low conductive targets only, high conductive targets only, or both high and low conductive targets. This feature offers a number of search options in concert with GB control adjustments. This subject is addressed in more detail later in the report.

Pulse Delay adjusts the sample pulse delay from 10-usec to 25-usec between the end of each transmitter pulse and the start of the receiver-sampling period. The 10-usec setting is the most sensitive to all targets including low conductive targets that comprise the vast majority of our silver nuggets and ores. Increasing the pulse delay towards 25-usec generally reduces overall target sensitivity, but minimizes ground mineral signals, and will suppress low conductive target signals such as small iron bits and low conductive silver.

Ground Balance Controls (fine and coarse) are activated by turning the Fine GB control clockwise to the ON position. With ground balance activated, the target conductivity control and variable audio are also activated.

The GB Control’s chief function is to compensate for ferromagnetic ground minerals. Most prospecting ground in northeastern Ontario’s silverfields will ground balance from 8½ to GB9 on the coarse GB Control scale.

The TDI Pro has manual ground balance only. Pump the coil one to six inches above the ground and adjust the coarse control until there is no change in threshold. Over some soils the fine control may be adjusted to fine tune the ground balance, but this is not necessary here. Any adjustment to the pulse delay will require another ground balance procedure if you intend to operate the unit in a ground-balanced condition.

If the ground mineral conditions permit, the GB control may be adjusted to achieve some discrimination control. The GB Control can be adjusted in conjunction with the target conductivity tone mode options to prevent a specific GB range from generating a signal. Alternately, these controls can be adjusted to hear all target signals, but assign a low or high conductive tone to target signals based on the GB Control position / setting on the ground balance scale. Targets that fall below the ground balance position will respond with a high conductive tone, whereas targets that lie above the ground balance setting will respond with a low conductive tone.

The GB Control setting impacts the depth that can be had on any given target. In light ground mineralizations, there is some ground balance adjustment latitude such that we can adjust the GB control to improve depth on a given GB target range while remaining ground-balanced. For example, let’s say we’re hunting low conductives. Low conductives mostly ground balance in the GB11 range. It is to our advantage to set the GB control as far below that range as possible to acquire best depth on low conductives and it will improve threshold stability.

Reducing the GB setting increases threshold stability as just noted. The GB1 setting is noticeably smoother and quieter to operate than GB9. Over lightly mineralized soils, the GB Control feature may not be required. It can be turned OFF to improve depth and threshold stability. However, operating with GB Control turned OFF means that the target conductivity tone mode is inactivated and that all targets respond with the same tone.

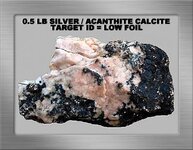

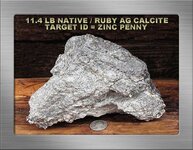

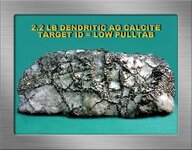

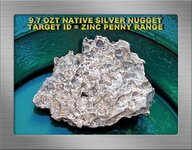

The photo below depicts a handsome half-pound acanthite / native silver specimen located with the TDI Pro. Acanthite is a silver sulfide comprising 87% silver and is often associated with wire silver here. It is quite soft and sectile, blackish and usually with a slight but distinctive deep bluish-black tint in this area. The native silver you see poking out of the rock runs right through it in veins. This specimen is strictly a low conductive tone mode signal. It does not produce a signal in the high conductive tone mode at any GB control setting, not even at the minimal GB11 position.

Benchtesting Metalliferous Rocks for Ground Balance

The ground balance point is the position on the GB control scale where a metal target will have its weakest signal. How do we locate a metal target’s ground balance?

Using the all-conductor tone mode a silver nugget might signal with a low conductive tone from GB1 clockwise to GB3, and a high conductive tone from GB5 clockwise to GB11. Mixed high and low tones will be heard in a transition zone between GB3 and GB5. GB4 is the null or ground balance point for this nugget. High and low tones will be about equal in volume and duration at the ground balance point.

Using the same silver nugget and the low-conductor tone mode a good signal is heard from GB1 clockwise to GB3 then gradually weakens and is gone at GB5. Switching to high-conductor tone mode, the nugget signals at GB11 counterclockwise to GB5 then gradually weakens and is gone at GB3. Again, the transition zone is from GB3 to GB5 and the null or ground balance point is GB4.

Target Signals / Iron Identification or Elimination

The ground balance scale runs from the GB1 position clockwise to the GB11 position. Target conductivity is highest at the GB1 position and decreases as the GB control is adjusted clockwise to the GB11 position. The lowest conductive targets fall into the GB11 category. As noted earlier, the signal tone with which a target responds depends on its GB point in relation to where the GB Control is set when employing the all-conductive tone mode. Normally in this area, the TDI Pro ground balances just below GB9, and that setting in the low-conductive tone mode is effective at eliminating the wide ferrous response pattern produced by nails and other high conductive iron signals. This response pattern doubtless results from iron’s conductive and magnetic properties. Even at GB9 some spurious / partial ferrous signals present themselves, but you quickly learn to recognize and ignore most of them.

This would be a good time to also point out that in a prospecting context where no two nuggets or specimens are exactly alike, that while there is an obvious general pattern, there is no absolute correlation between VLF target ID and TDI Pro GB settings. For example, two nuggets with identical VLF target ID frequently occupy different GB positions due to their differing physical traits and chemical constituents. And vice-versa is also true.

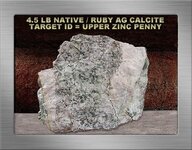

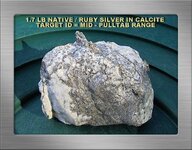

Low conductive silver predominates in this area. It is impossible to separate it from low conductive iron trash since both occupy a similar GB range. Perhaps some operators feel that they can distinguish such iron from non-ferrous targets, but I think there is too much variability with target size, shape, depth and profile to the coil to have any real confidence in attempting to do so. On a more positive note, a typical ground balance setting of GB9 in concert with the low-conductive tone mode will capture low conductive silver that generally exists at or below the full pulltab range, but silence most higher conductive iron including most nails. I think we can agree that capability is a real bonus from a PI unit.

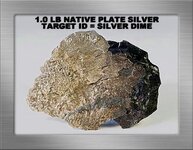

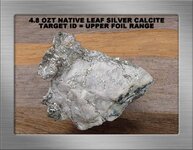

As VLF target ID increases beyond the upper pulltab range, there is considerably less higher conductive silver detected in abandoned waste tailings disposal areas. High conductive iron and high conductive silver occupy a similar ground balance range, but high conductive iron is far more plentiful, and is predominately variably sized nails. Employing a typical ground balance setting of GB9 in concert with a high-conductive tone mode will capture high conductives including silver that generally exists at or above the upper pulltab range, but will silence low conductive iron trash and low conductive silver.

There is a technique available to help with separating high conductive iron signals from all silver. It can save you a lot of difficult digging in hardpacked rocky substrates. In a prospecting context, the technique is definitive at identifying high conductive iron if a low-high-low iron tone signal can be obtained. It is as simple as sweeping the coil across a target from different directions while operating the TDI Pro in the all-conductive tone mode at the usual GB9 setting give or take a bit. If you can’t acquire a low-high-low iron tone, try adjusting the GB Control closer to the target’s GB point, and slightly offset it if necessary to discern the signal more clearly. If you can’t acquire the low-high-low iron tone, then you must dig the target. If you do acquire it, you can ignore the target because it is definitely iron and probably elongated iron such as nails, spikes, or drillrods.

The GB control adjustment technique does not always acquire a lo-hi-lo tone over some high conductive iron. Compact iron such as large milling balls, drillbits, and other nondescript chunky iron possess very “tight” GB spans similar to silver or gold. Over such targets, low-high-low iron tones are difficult to acquire without some delicate GB control adjustment, and you have to listen carefully. Elongated iron items like nails, bolts and drillrods normally present no difficulty obtaining the iron tone and usually don’t require much or any GB adjustment if you’re already operating around GB9.

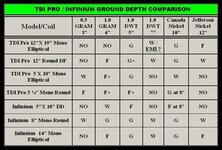

TDI Pro & Infinium Depth Comparison

Operated at bare thresholds the TDI Pro is a noticeably deeperseeking and more sensitive unit. The Garrett Infinium’s depth / sensitivity is improved by adjusting the threshold control up to 6ish or slightly more and adjusting headphone volume to preference. With this adjustment to Infinium there is little or no difference between these units regarding depth / sensitivity over a variety of target sizes buried at variable depths in my testplot. There is some variability between different types and sizes of coils of course. We see that large coils tend to be deeperseeking on larger targets and less sensitive to shallower small stuff and vice-versa for small coils. Mono coils are deeperseeking compared to similar size DD coils in this moderately difficult ground. Infinium’s mono coils are more likely to signal over high conductive large iron with an iron indicative lo-hi tone than is the case with DD coils. More information on this and other topics can be had at the revised April / 2015 Garrett Infinium Report located at this link… http://www.treasurenet.com/forums/c...erfields-ontario-revised-february-2011-a.html.

Now let’s look at some low conductive target responses presented in the chart below. As noted above, the majority of silver ores are low conductive. Keep in mind these depths do not represent the full capability of these units. Using solid lead “nuggets” instead of gold or silver nuggets, the fact that they’re freshly buried, and rather severe local EMI conditions all contrive to reduce detection depth compared to silver or gold nuggets naturally occurring in the field. But they do work just fine for relative side-by-side depth comparisons between these units.

For this comparison, Infinium threshold is set slightly above six (6), employs zero discrimination, with the ground balance control locked after ground-balancing the unit. The TDI Pro is manually ground-balanced at just below GB9, set to near maximum gain, with a 10-usec-pulse delay and a bare threshold. The chart designations indicate Weak, Fair, and Good signal responses.

I tend to compare the 8” Infinium round mono to the TDI designed Razorback 5 X 10” elliptical mono, and the Infinium 10” X 14” elliptical mono to the TDI Pro 12” DF round stock coil because these are comparable sizes. I think we can agree that the results are fairly close, the variances are likely due to the coils tested. I see no significant advantage either way on these low conductive targets, but certainly the Infinium 8” round mono searchcoil performs very well over the entire target size / depth range.

Both these units have been used extensively in the field for several prospecting seasons. Operating as described, I’ve not noticed any discernable depth difference between them. But in lighter ferromagnetic mineralizations, the TDI Pro’s ground balance control can be seriously reduced or even turned-off, and such adjustments produce significant extra depth and sensitivity to a wide target size range. It ‘s difficult to assign a hard number due to size and depth variability of silver ores, and frankly I normally don’t measure target depths in the field. But lengthy experience with this unit leaves me with no doubt that this is certainly the case.

To place the chart into a sensible perspective, we should note that there are a number of factors that affect depth results at any given time or place. These factors include difficult ferromagnetic minerals, disturbed or undisturbed soil conditions, soil moisture, electromagnetic (EMI) interference, physical / chemical characteristics of a target, detector settings, operator skill and so forth. It’s not unusual to encounter situations where a deep target in the test plot can easily be had one week, while the following week it is difficult to acquire a decent signal from the same target. The only factors that could have changed are soil moisture and EMI levels.

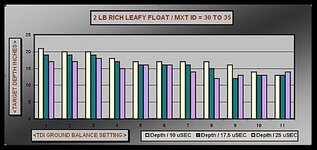

The bar graph below has been included to illustrate what has previously been discussed in this report. The bar graph depicts an air test depth trend with a hefty low conductive silver specimen as the ground balance control is adjusted throughout its entire range. The depth loss at a 10-usec-pulse delay from GB1 to GB11 is rather significant as you can see. Silver samples with the same ground balance point as the GB Control operating position can be completely eliminated from detection, while samples residing anywhere near the GB Control operating position will produce very poor signals that result in greatly reduced detection depth. Regardless whether these air depths accurately reflect buried target depths, the data certainly suggests using as low a GB setting as ferromagnetic ground minerals permit to achieve best depth when searching low conductive silver ores and nuggets. The same doubtless applies to gold.

Vanishing PI Signals on Small / Specimen Silver

We sometimes read about hobbyists claiming that nuggets in the ground react with a stronger signal to their PI units than those same nuggets produce once on the surface or waved across the coil. Some occasionally claim that no air test signal can be had on a piece that obviously responded with a signal when in the ground. From my experience with the TDI Pro and Garrett Infinium I have no doubt these accounts are factual.

But on the other hand, there are also plenty of samples dug from various depths that do not react similarly. For example, the deeper, larger solid structure silver ores produce weak signals entirely due to depth, but when brought to the surface these same pieces… of course… produce a very strong signal.

One could postulate that there is a combination of factors such as size, shape, structure and depth that determine differences in signal strength for any given target once brought to and scanned on the surface. My observation is that signal strength loss on the surface seems to be restricted to smaller shallow silver and sometimes it occurs with slightly larger ‘high character’ or spongy silver a bit deeper. A decent size piece is anticipated based on the signal strength, only to dig it and find that a perfectly good signal was produced by small or sponge silver whose surface signal has lost considerable strength or nearly vanished. Occasionally the signal is lost altogether… requiring my Propointer to locate such targets.

Search Techniques in the Field

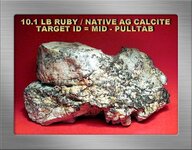

The vast majority of our native silver is considered to be low conductive, meaning that most of it falls into a VLF target ID range from low foil up to and including the full pulltab range. Searching in a ground-balanced condition at GB9 in the low-conductive tone mode captures all low conductive silver. Our more difficult ferromagnetic mineralized substrates consistently ground balance just below the GB9 Control setting, a convenience insofar as that setting pretty well eliminates any remaining spurious / partial nail signals and most other high conductive iron trash. Unfortunately, it also eliminates the much less prevalent but valuable high conductive silver.

The above operating technique is my preference for hunting silver with the TDI Pro. It is much more productive in waste tailings disposal areas inundated with iron trash than any other available technique. But if one wishes to hear signals from the entire GB range, and that is normally my preference when searching for high conductive silver, we can select the all-conductive tone mode. It tells us whether a target signal is a high or low conductive, and we benefit from the low-high-low iron tones available in this mode. As a result, the high-conductive tone mode doesn’t see much use in the silverfields by me.

In areas of lighter ferromagnetic mineralizations reasonably free of iron junk, one can comfortably search in the low-conductive tone mode with the ground balance reduced to GB1 or thereabouts. The GB1 position permits the entire silver GB range to respond, while generating the best possible depth to low conductives.

At GB1 in low-conductive tone mode, some ground minerals may prompt a low conductive tone volume increase as the coil is lowered within an inch or two of the ground. This was no issue here since the coil needs to be held several inches above the uneven rocky substrates to avoid smacking the coil. Where possible try to maintain a reasonably level coil height, especially if using high gain, and slow down your sweep speed to help attenuate ground noise. If these are insufficient to reduce the ground noise then, try reducing the gain, followed by adjusting the ground balance clockwise if necessary, until effective searching is possible.

All low conductive iron signals must be dug to ensure low conductive silver is not overlooked, so be prepared to dig plenty of small iron. Although the TDI Pro arguably can discern target size particularly when using the low-conductive tone mode, it is very difficult to evaluate most low conductive signals with any confidence when target size and depth are highly variable factors. Increasing the pulse delay to assess signal strength is not a viable technique because it affects low conductive iron trash signals similarly to low conductive silver.

Some Comparative Iron Testing

Early in the trip we decided to compare some signals between the TDI Pro and the Infinium. Signals were located and flagged with the Infinium, and then rechecked with the TDI Pro.

This location had an abundance of 3 ½ ” by roughly 1/3” thick rail spikes with a solid 1” diameter cap. None were beyond an eight or nine inch depth. Infinium identified these as lo-hi signals in zero discrimination and again in reverse discrimination clearly indicating iron targets in a prospecting context. Yes, there are very rare examples of silver producing a VLF target ID above the silver dime range that would respond with a reverse discrimination low-high signal, but these are so highly improbable as to be considered almost non-existent here. Certainly not a realistic factor when establishing a sensible or practical search strategy exploiting the Infinium’s automated tones in both zero and reverse discrimination. More on this subject shortly.

TDI Pro signaled nicely over all these targets with a low-high-low iron tone at GB9 in the all-conductive tone mode. And a precise setting of GB9 was not necessary to obtain the iron tone because there is plenty of GB latitude / forgiveness over elongated iron. A drillrod roughly five (5) inches long with a one-inch diameter was found at a half-foot depth. Both units correctly identified it as high conductive iron by the same means as described for the rail spikes.

A Word about Searching with Infinium

The Infinium identifies high and low conductives more conveniently with an automated tone system, and without manipulation of any controls to identify some high conductive iron. At zero discrimination high conductives produce a lo-hi signal and low conductives produce a hi-lo signal. Infinium automatically performs this task and does so pretty much to its detection depth limit. There have been a few instances over the years where the unit defaulted to a hi-lo tone over a target buried at its absolute maximum detection depth. In each instance, as digging reduced the coil to target distance, the hi-lo signal changed over to a lo-hi signal to correctly identify a high conductive iron target. At least this initial hi-lo tone response ensures the target will be investigated.

At zero discrimination, the Infinium produces a hi-lo low signal on all ferrous and non-ferrous targets that occupy a low conductive range up to low zinc penny range. High conductive lo-hi signals represent all targets with conductive values above low zinc penny range.

In reverse discrimination, the Infinium produces a hi-lo low conductive signal on all ferrous and non-ferrous targets that occupy an expanded conductive range up to and including silver dime range. In a prospecting context, lo-hi signals in reverse discrimination represent iron targets with VLF target ID values above the silver dime range. Naturally occurring silver that will respond with a lo-hi signal in reverse discrimination is so extremely rare as to be considered practically non-existent in this area. But remember that no discrimination system is infallible. It would be foolish not to investigate broad, deep weak signals no matter what tone the Infinium produces.

All zero discrimination lo-hi tone targets, ferrous and non-ferrous, within the range from low zinc penny up to and including silver dime obviously change tone in reverse discrimination to produce a low conductive hi-lo tone signal. But high conductive iron is far more plentiful than high conductive silver in this narrow conductive range. To avoid digging such iron in excessively trashy areas, you may prefer to stick with zero discrimination tones only. The trade-off is ignoring infrequent high conductive silver, but this strategy frees up a lot of time to cover much more ground. Reverse discrimination hi-lo signals should otherwise always be recovered, but this technique is worth keeping in mind in trashy areas.

In summary, zero discrimination low conductive hi-lo signals remain hi-lo signals in reverse discrimination. Some signals lose much or all of their signal strength when checked in reverse discrimination. Some zero discrimination lo-hi signals will change to hi-lo signals in reverse discrimination. All these signals must be dug if one intends to avoid overlooking any silver.

To ensure effective target ID, always sweep the coil over a target from different directions. Any target that produces both hi-lo and lo-hi signals in zero discrimination is in all probability iron. Elongated iron will give a lo-hi or double lo-hi signal along its length and usually… but not always… a hi-lo signal across its width.

The reverse discrimination concept of reduced signal volume over non-ferrous targets is not a definitive technique and should be used as an indicator only, insofar as you can dig with some extra enthusiasm. Certainly most silver ores lose considerable signal strength in reverse discrimination, but sturdier or massively structured high conductive silver tends to retain its signal strength similar to large high conductive iron. By contrast, small low conductive iron can lose signal strength in reverse discrimination similar to low conductive silver.

A Final Word About the TDI Pro

The primary reason for PI usage is to improve depth over VLF units in difficult ferromagnetic mineralizations. In such conditions, employing larger coils further enhances PI depth capability compared to VLF units equipped with similar size coils. It is a significant advantage of PI units over VLF units.

PI units tend to ignore most non-conductive, iron-mineralized hotrocks encountered in the silverfields. Our diabase rocks demonstrate both a magnetic susceptible strength and ground phase variability, so no two rocks are absolutely identical in that regard. When searching in a diabase substrate at many sites, they generate both positive and negative VLF signals, and their typical multi-pound size range tends to obscure small silver VLF signals. But the TDI Pro performed flawlessly over diabase hotrocks and other infrequently encountered mafics here, permitting detection of deeper silver that in at least some instances would surely have been overlooked by VLF units.

We have placed a lot of emphasis on the TDI Pro’s iron handling capability in this report because it is an important issue here, where nearly all the old minesite buildings have been dismantled. Many of our minesites had massive, multi-story buildings, and as many as twenty-five buildings located in a single mining camp. The lumber has mostly been removed, but countless nails and spikes, railspikes, drill rods, drillbits, implements, tools, machinery parts, fuel containers, and a wide variety of other non-descript iron trash inundates the mining camps and waste tailings disposal areas. Most is at or near the surface, but a considerable portion exists at variable depths, and is no fun to dig in difficult, hardpacked rocky substrates.

Collectible or desirable silver is normally much larger than gold, our recoveries are frequently in the multi-ounce and multi-pound range. These signals can easily be confused with high conductive iron signals, particularly compact iron such as larger drillbits and milling balls, and other chunky non-descript iron trash. The TDI Pro operated in the all-conductive tone mode in the vicinity of GB9 is effective at identifying elongated iron such as drillrods and nails with a definitive low-high-low iron signal, but it is somewhat less effective at identifying compact iron. With time-consuming, delicate GB control adjustments we can sometimes obtain a weak low-high-low signal from compact iron, but that is frequently not the case and we have to dig such signals. But there is an alternative search strategy….

The Pro’s chief attribute here is its ability to eliminate nail signals and most other high conductive iron trash by searching for low conductive silver in low-conductive tone mode at GB9. This is a very convenient set of circumstances insofar as the vast majority of our nuggets and ores are low conductives. That capability combined with a serious reduction in audio signals, makes the TDI Pro ideal at sites that otherwise would be difficult or impossible to properly search with the Infinium or other PI units. A 10” elliptical mono or 5 ¼” round mono combined with a very slow sweep speed enhances target separation while acquiring the best depth possible for those coils.

The fact of the matter is that any help we can get from manufacturers to produce PI units with any iron-handling capability is a welcome bonus. The TDI Pro possesses unique features to deal with iron as described in this report. To definitively identify high conductive iron at depth with a low-high-low iron tone is real and encouraging progress for handling iron trash that is superior to VLF phase shift technology as it exists today at least for this application. These same high conductive iron targets, including some elongated iron such as the five or six inch long by one inch diameter drillrods at depth have completely fooled VLF discrimination for nearly thirty years. The TDI Pro’s iron-handling capability is described here as its chief attribute because it saved me from extensive effort digging iron trash from difficult, hardpacked rocky substrates.

I would like to thank my friend, geologist Dr. Jim Eckert of northeastern Ontario, for his many helpful contributions to this report. Jim and I worked together to evaluate how to effectively operate the TDI Pro to search for silver. We would like to acknowledge and thank our good friend Reg Sniff from Pueblo, Colorado for his tireless contributions to the metal detecting community for many years. He has generously helped us to understand the fundamentals of PI metal detector operation, particularly the TDI series… he is a true Pathfinder.

Jim Hemmingway

Revised April 2015

Amazon Forum Fav 👍

Last edited:

Upvote

0