KurtB

Jr. Member

I am going to modify my sluice to a highbanker. The riffles are 3/8" high. Do I need to increase the size of the riffles to work with the increased water flow? Any suggestions on a good grizzly design?

Thanks

Kurt

Thanks

Kurt

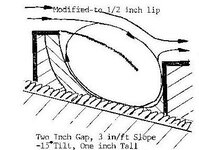

). I was assuming I needed to remove the expanded metal from my A-52 highbanker/2.5" dredge conversion now that I was finally getting around to putting in the dredge/highbanker riffles. I've used it for years with the original (only a few times a year) so I guess it's about time. Lowered the angle of the grizzly so it doesn't shed material quite as fast. I also put a plate in the hopper that directs the slurry to the very top of the sluice rather than dumping it straight down. Punch plate for the 1st foot of the sluice, then about 8" of nothing(but carpet), then the riffles. Ribbed carpet from one end to the other. Need to put in a light rubber flap near the top to smothe the flow a bit.

). I was assuming I needed to remove the expanded metal from my A-52 highbanker/2.5" dredge conversion now that I was finally getting around to putting in the dredge/highbanker riffles. I've used it for years with the original (only a few times a year) so I guess it's about time. Lowered the angle of the grizzly so it doesn't shed material quite as fast. I also put a plate in the hopper that directs the slurry to the very top of the sluice rather than dumping it straight down. Punch plate for the 1st foot of the sluice, then about 8" of nothing(but carpet), then the riffles. Ribbed carpet from one end to the other. Need to put in a light rubber flap near the top to smothe the flow a bit.