Goodyguy

Gold Member

- Mar 10, 2007

- 6,489

- 6,900

- Detector(s) used

- Whites TM 808, Whites GMT, Tesoro Lobo Super Traq, Fisher Gold Bug 2, Suction Dredges, Trommels, Gold Vacs, High Bankers, Fluid bed Gold Traps, Rock Crushers, Sluices, Dry Washers, Miller Tables, Rp4

- Primary Interest:

- All Treasure Hunting

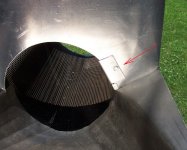

Bought a Gold Cube off Craigslist and decided to build a trommel for it that I could also use on a regular highbanker or over a sluice.

I have plenty of scrap material leftover from other projects so my out of pocket costs will be pretty low.

Here are some of the materials I started the project with.......

31" square sheet of 1/8" punchplate for the drum.

1/8" thick aluminum scraps and a large 1/8" piece of aluminum sheet.

(1) 12V motor I had saved from an electric seat off my old car.

(4) wheels from an old pair of skates.

(1) 10" diameter stainless steel stock pot that we never used.

(1) length of 3/4" angle aluminum.

I have plenty more scraps that will go into the trommel but this is what I'm starting out with for the first part of the build.

GG~

I have plenty of scrap material leftover from other projects so my out of pocket costs will be pretty low.

Here are some of the materials I started the project with.......

31" square sheet of 1/8" punchplate for the drum.

1/8" thick aluminum scraps and a large 1/8" piece of aluminum sheet.

(1) 12V motor I had saved from an electric seat off my old car.

(4) wheels from an old pair of skates.

(1) 10" diameter stainless steel stock pot that we never used.

(1) length of 3/4" angle aluminum.

I have plenty more scraps that will go into the trommel but this is what I'm starting out with for the first part of the build.

GG~

Last edited:

..........................

..........................