Goodyguy

Gold Member

- Mar 10, 2007

- 6,489

- 6,900

- Detector(s) used

- Whites TM 808, Whites GMT, Tesoro Lobo Super Traq, Fisher Gold Bug 2, Suction Dredges, Trommels, Gold Vacs, High Bankers, Fluid bed Gold Traps, Rock Crushers, Sluices, Dry Washers, Miller Tables, Rp4

- Primary Interest:

- All Treasure Hunting

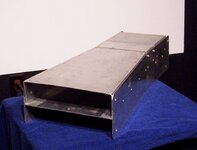

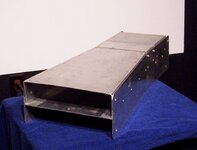

Tired of losing the flour and fine Gold off the end of your highbanker or sluice ?

Then build a combination sluice/fluid bed trap to end the lost gold blues!

No Riffles, No need to classify, No lost gold.

My version does not load up with rocks that have to constantly be cleared off the grizzly as on the commercial models.

The reason is .....I designed mine to be flat and level with the sluice by dropping the bed of the sluice just in front of the trap instead of building an uphill grizzly, that way there is nothing for the larger gravel to get hung up on. The red arrow is pointing to the nugget trap area in front of the grizzly.

On the test version I had installed a plexiglass cover over the trap so I could monitor the operation.

Placed at the end of a high banker sluice for a final gold catcher you will be assured of capturing any missed gold.

Of course you have to supply water to the stratification tubes but since you already are using a pump for your highbanker just run a separate line to them with a control/shut off valve and only allow about 9 gallons (plus or minus) per minute into them. (adjust as needed)

Or just use it all by itself as a stand alone fluid bed hand sluice...either way you trap the gold

Total cost of materials to build it $35 Peace of mind knowing that you wont lose any gold.......Priceless

Legs are from crutches.

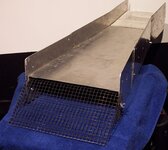

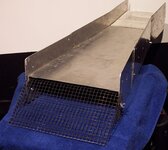

The trap is 2-1/2" inches deep. The holes in the stratification tubes are 1/8" dia. and are spaced 1/2" apart and go through both sides. The 5/8" OD 1/2" ID CPVC tubes are centered 1" off the bottom of the trap and are spaced 2-1/2" apart on centers from center tube.

The trap over flow is a 3/4" opening while the trap intake is a 1/2" opening. The 1/2" expanded metal is fastened underneath the 1/4" plexiglass.

Manifold and hose set up for use with a high banker. (Adj. bottom cover off for photo)

Adjustable scoop for slow flow conditions....

When the water velocity through the stratification tubes is adjusted properly all the material in the trap stays in suspension except for the heavier gold, it stays on the very bottom while the lighter material continually keeps running out the overflow end of the trap.

* added a self clearing leaf guard.

Made from 1/2" heavy duty hardware cloth.

Go for the gold

GG~

Then build a combination sluice/fluid bed trap to end the lost gold blues!

No Riffles, No need to classify, No lost gold.

My version does not load up with rocks that have to constantly be cleared off the grizzly as on the commercial models.

The reason is .....I designed mine to be flat and level with the sluice by dropping the bed of the sluice just in front of the trap instead of building an uphill grizzly, that way there is nothing for the larger gravel to get hung up on. The red arrow is pointing to the nugget trap area in front of the grizzly.

On the test version I had installed a plexiglass cover over the trap so I could monitor the operation.

Placed at the end of a high banker sluice for a final gold catcher you will be assured of capturing any missed gold.

Of course you have to supply water to the stratification tubes but since you already are using a pump for your highbanker just run a separate line to them with a control/shut off valve and only allow about 9 gallons (plus or minus) per minute into them. (adjust as needed)

Or just use it all by itself as a stand alone fluid bed hand sluice...either way you trap the gold

Total cost of materials to build it $35 Peace of mind knowing that you wont lose any gold.......Priceless

Legs are from crutches.

The trap is 2-1/2" inches deep. The holes in the stratification tubes are 1/8" dia. and are spaced 1/2" apart and go through both sides. The 5/8" OD 1/2" ID CPVC tubes are centered 1" off the bottom of the trap and are spaced 2-1/2" apart on centers from center tube.

The trap over flow is a 3/4" opening while the trap intake is a 1/2" opening. The 1/2" expanded metal is fastened underneath the 1/4" plexiglass.

Manifold and hose set up for use with a high banker. (Adj. bottom cover off for photo)

Adjustable scoop for slow flow conditions....

When the water velocity through the stratification tubes is adjusted properly all the material in the trap stays in suspension except for the heavier gold, it stays on the very bottom while the lighter material continually keeps running out the overflow end of the trap.

* added a self clearing leaf guard.

Made from 1/2" heavy duty hardware cloth.

Go for the gold

GG~

Last edited: