mess'n round with new sluice,any ideas?

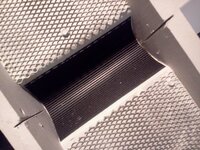

i cant afford to buy my toys,i have to make them,this is one of my projects,figured i would see what some of you thought.if i ican get it to the piont where i am satisfied with it i may scale it up.so far my best results are when ,its dead level,if i start to add drop ,it gets to bioling ,so have decrease velocity of water,when i do this it tends to build up,but when level,and water pressure cranked,with 1500gph,it seems to do quite well,now i havent had it on gold yet, but i've done lead tests ,with flurescent painted filings,and seems good,first (gate) i have set at3/8in above ribbed matting,lots of velocity,2nd gate is5/16 in above rib mat,3rd is1/2 in no mat,then xpanded metal,4th is5/8in no mat then xpanded metal.i class everything down to 1/4 . just thought i would like to here any sugestions to improve.i just wanted to see if i could get cleaner cons with something like this.

i cant afford to buy my toys,i have to make them,this is one of my projects,figured i would see what some of you thought.if i ican get it to the piont where i am satisfied with it i may scale it up.so far my best results are when ,its dead level,if i start to add drop ,it gets to bioling ,so have decrease velocity of water,when i do this it tends to build up,but when level,and water pressure cranked,with 1500gph,it seems to do quite well,now i havent had it on gold yet, but i've done lead tests ,with flurescent painted filings,and seems good,first (gate) i have set at3/8in above ribbed matting,lots of velocity,2nd gate is5/16 in above rib mat,3rd is1/2 in no mat,then xpanded metal,4th is5/8in no mat then xpanded metal.i class everything down to 1/4 . just thought i would like to here any sugestions to improve.i just wanted to see if i could get cleaner cons with something like this.

i cant afford to buy my toys,i have to make them,this is one of my projects,figured i would see what some of you thought.if i ican get it to the piont where i am satisfied with it i may scale it up.so far my best results are when ,its dead level,if i start to add drop ,it gets to bioling ,so have decrease velocity of water,when i do this it tends to build up,but when level,and water pressure cranked,with 1500gph,it seems to do quite well,now i havent had it on gold yet, but i've done lead tests ,with flurescent painted filings,and seems good,first (gate) i have set at3/8in above ribbed matting,lots of velocity,2nd gate is5/16 in above rib mat,3rd is1/2 in no mat,then xpanded metal,4th is5/8in no mat then xpanded metal.i class everything down to 1/4 . just thought i would like to here any sugestions to improve.i just wanted to see if i could get cleaner cons with something like this.

i cant afford to buy my toys,i have to make them,this is one of my projects,figured i would see what some of you thought.if i ican get it to the piont where i am satisfied with it i may scale it up.so far my best results are when ,its dead level,if i start to add drop ,it gets to bioling ,so have decrease velocity of water,when i do this it tends to build up,but when level,and water pressure cranked,with 1500gph,it seems to do quite well,now i havent had it on gold yet, but i've done lead tests ,with flurescent painted filings,and seems good,first (gate) i have set at3/8in above ribbed matting,lots of velocity,2nd gate is5/16 in above rib mat,3rd is1/2 in no mat,then xpanded metal,4th is5/8in no mat then xpanded metal.i class everything down to 1/4 . just thought i would like to here any sugestions to improve.i just wanted to see if i could get cleaner cons with something like this.