go4thegold

Greenie

- May 14, 2014

- 12

- 9

- Primary Interest:

- Prospecting

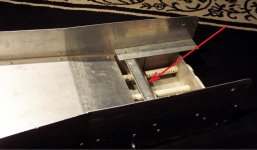

I'm currently building a gold trap box.

My only problem has been that I haven't been able to get a picture of the end of the box itself. (where the trap is)

I've been wanting to see a picture of the overflow cutout/ exit side. If you've made your own or have a bazooka I would love a picture.

My box is made of sheet metal and it's turning out pretty good. I will be adding pvc pipes to the gold trap to keep a steady stream of water coming in to keep the material in a liquefied state.

Pictures to come of it soon.

Thanks!

My only problem has been that I haven't been able to get a picture of the end of the box itself. (where the trap is)

I've been wanting to see a picture of the overflow cutout/ exit side. If you've made your own or have a bazooka I would love a picture.

My box is made of sheet metal and it's turning out pretty good. I will be adding pvc pipes to the gold trap to keep a steady stream of water coming in to keep the material in a liquefied state.

Pictures to come of it soon.

Thanks!

Amazon Forum Fav 👍

Upvote

0