jog

Bronze Member

- Nov 28, 2008

- 1,364

- 682

- Detector(s) used

- Whites MXT / GMT

- Primary Interest:

- All Treasure Hunting

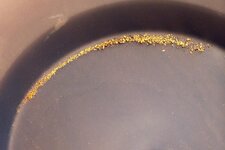

When I built my trommel I also built a 16"W by 5'L sluice. I have been testing this box with riffles and expanded metal but think I would get better results from a smaller box. What I'm looking for is some good ideas on different types of box's and riffle design. The screen classifies down to 1/2" and I am using a Honda 2" trash pump. I believe it's putting out 158Gal per min. I will have to double check on that. Does anyone know if a LeTrap sluice or one of the Angus Mackirk sluice box's would work on a trommel?

Also made a modification to the water spray bar system but don't have a pic yet, will post one when I get one.

Thanks for any input.

Also made a modification to the water spray bar system but don't have a pic yet, will post one when I get one.

Thanks for any input.

Upvote

0