N-Lionberger

Bronze Member

- Dec 1, 2013

- 1,427

- 2,074

- Detector(s) used

- Fisher 1212-x

Fisher Gold Bug 2

Whites 4900/SP3

Dowsing rods

- Primary Interest:

- Prospecting

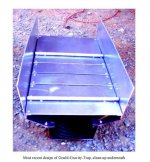

https://www.gouldeng.com/trap.htm

Winners posted the old gould engineering website in response to a question on dredge theory, I havent looked at it in a while, fun reading. Anyways I saw the highbanker has anyone on here ever seen one in person?

Winners posted the old gould engineering website in response to a question on dredge theory, I havent looked at it in a while, fun reading. Anyways I saw the highbanker has anyone on here ever seen one in person?