Jeff95531

Silver Member

- Feb 10, 2013

- 2,625

- 4,094

- Detector(s) used

- Teknetics Alpha 2000

- Primary Interest:

- Prospecting

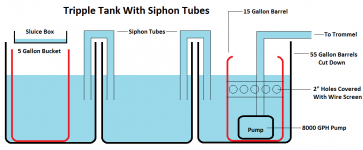

Is a DIY sluice ever really done? Boy have I learned a lot about theory, practice and patience. I originally was going to use this on the bank where I would be prospecting. But as costs soared and regulations tightened, I had to adapt it for home use. My first try resulted in several obvious problems. Sprayers needed to be aimed, drop was not enough, losing water in all kinds of places, front legs out too far for the catch basin to catch the flow, back legs too long, catch basin not wide enough for sluice clean out and finally, not near enough water pressure and plugging of holes due to sediment. Fixed all those problems (except for the pump). The pump box had a list of specs I really needed to know before I bought it. Like this:

Wire size: 16GA (I used 12)

Fuse size 10 amp. (I installed a 20 and when I went to change the fuse to a 10, I found I couldn't. Next time buy the newer style plug in.

Hose size max 1 1/4" (I have 1 1/2")

Max height of lift 7" (I'm at 44"!)

It's a wonder it works at all!

Anyway, if I had to do it again, I would go to a 4000GPH. Since that was not an option, I fixed the following.

Removed the check valve and the 50% flow restrictor behind it. Lowered the overall height. Trimmed the supply hose to minimum length.

Other wastes of time and money:

I wanted a hand held sprayer to rinse the sluice. The reality is the valve is too tight to turn (sound familiar?) and when it was shut off, it blew apart press fit stuff that I was NOT going to glue. All the plumbing is press fit or threaded. I used one 9" piece of plumbers tape to hold the assembly at head in place. That's it! Also, reducing water flow from inch and a half to 3/8? Soooo not worth it. Tossed the entire sprayer assembly aside. The shut off valve remains but is unused. The toggle on/off switch works perfect.

Added levels front and back. Bought wood shims (for installing doors) to level the sluice. Still only one inch drop and it was loading up. Went to a five inch drop and perfect! No more loading up and had no noticeable loss of water this time. Yea! Bought and installed 2 two inch wheels and installed in the back. Note: Do NOT buy swivel wheels, only fixed wheel! Even walking slow I still managed to flip it. Those have to be replaced.

Anyways, here is a cost list. I found out from a member here that the plans for the identical sluice are available and less than $20. I don't have the site right now, but that would have helped a great deal. Way back when, all I could find was the pics. We were using a ruler for scale on the pics because we knew the LeTrap was 4 feet long.

LeTrap $70.00

2200GPH $80.00

Hose $20.00

Stain $10.00

2x4’s $7.00

Tubs $25.00

Batt Charger N/C

Wiring $18.00

Switch, fuse

Hardware $30.00 (stainless steel and brass, wood shims, levels, wheels)

Labor N/C

PVC&Hand

Sprayer $40.00

$300.00

Here are the pics and a short video. The video quality is awful, but my phone was all I had to work with at the time.

With 2 1/2 gallons of unclassified material, I got 6 small flakes after I panned the concentrates. That wasn't bad for the spot I picked. Felt really good to add to my vile again.

Comments and critiques are encouraged.

Jeff

Wire size: 16GA (I used 12)

Fuse size 10 amp. (I installed a 20 and when I went to change the fuse to a 10, I found I couldn't. Next time buy the newer style plug in.

Hose size max 1 1/4" (I have 1 1/2")

Max height of lift 7" (I'm at 44"!)

It's a wonder it works at all!

Anyway, if I had to do it again, I would go to a 4000GPH. Since that was not an option, I fixed the following.

Removed the check valve and the 50% flow restrictor behind it. Lowered the overall height. Trimmed the supply hose to minimum length.

Other wastes of time and money:

I wanted a hand held sprayer to rinse the sluice. The reality is the valve is too tight to turn (sound familiar?) and when it was shut off, it blew apart press fit stuff that I was NOT going to glue. All the plumbing is press fit or threaded. I used one 9" piece of plumbers tape to hold the assembly at head in place. That's it! Also, reducing water flow from inch and a half to 3/8? Soooo not worth it. Tossed the entire sprayer assembly aside. The shut off valve remains but is unused. The toggle on/off switch works perfect.

Added levels front and back. Bought wood shims (for installing doors) to level the sluice. Still only one inch drop and it was loading up. Went to a five inch drop and perfect! No more loading up and had no noticeable loss of water this time. Yea! Bought and installed 2 two inch wheels and installed in the back. Note: Do NOT buy swivel wheels, only fixed wheel! Even walking slow I still managed to flip it. Those have to be replaced.

Anyways, here is a cost list. I found out from a member here that the plans for the identical sluice are available and less than $20. I don't have the site right now, but that would have helped a great deal. Way back when, all I could find was the pics. We were using a ruler for scale on the pics because we knew the LeTrap was 4 feet long.

LeTrap $70.00

2200GPH $80.00

Hose $20.00

Stain $10.00

2x4’s $7.00

Tubs $25.00

Batt Charger N/C

Wiring $18.00

Switch, fuse

Hardware $30.00 (stainless steel and brass, wood shims, levels, wheels)

Labor N/C

PVC&Hand

Sprayer $40.00

$300.00

Here are the pics and a short video. The video quality is awful, but my phone was all I had to work with at the time.

With 2 1/2 gallons of unclassified material, I got 6 small flakes after I panned the concentrates. That wasn't bad for the spot I picked. Felt really good to add to my vile again.

Comments and critiques are encouraged.

Jeff

Amazon Forum Fav 👍

Last edited:

Upvote

0