omnicron

Bronze Member

Hey guys, last night I woke up with a idea. I've looked over the net and haven't found any info on this, maybe because it doesn't exist or doesn't work. Lets put our heads together and figure out the pro's and cons.

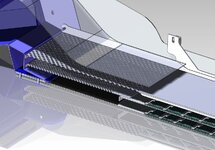

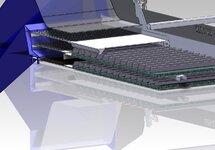

So what I'm thinking is a standard 4" dredge box is 16" wide. Without having to upgrade the pump to supply more water the logical step would be to make the box narrower, say 14"

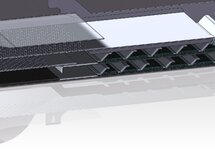

Then for the lowest sluice section you would make it less then 1" tall and use 1/2" raised expanded.

The middle box you would make it about 1.5" tall or a little less and could use 3/4" raised expanded.

The top part would be standard to low profile riffles.

Logic says that fine gold recovery is achieved when the same sized material is ran together so each section would be classified via punch plate in stages. Say 1/2 top section, 5/16 or 3/8" and bottom section would be 3/16 or 1/8"

Anyone care to chime in on this?

So what I'm thinking is a standard 4" dredge box is 16" wide. Without having to upgrade the pump to supply more water the logical step would be to make the box narrower, say 14"

Then for the lowest sluice section you would make it less then 1" tall and use 1/2" raised expanded.

The middle box you would make it about 1.5" tall or a little less and could use 3/4" raised expanded.

The top part would be standard to low profile riffles.

Logic says that fine gold recovery is achieved when the same sized material is ran together so each section would be classified via punch plate in stages. Say 1/2 top section, 5/16 or 3/8" and bottom section would be 3/16 or 1/8"

Anyone care to chime in on this?

Im an inventor and that honestly sounds like a good plan, I mean self classifying and concentrating. You could run ALL day without a cleanup and start and stop without worrying about blowouts. Im looking forward to hanging out with you OMNI. You seem like a wise cat.

Im an inventor and that honestly sounds like a good plan, I mean self classifying and concentrating. You could run ALL day without a cleanup and start and stop without worrying about blowouts. Im looking forward to hanging out with you OMNI. You seem like a wise cat.