Astrobouncer

Hero Member

- Jun 21, 2009

- 823

- 344

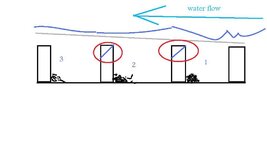

I built this sluice out of some scrap wood in my garage.

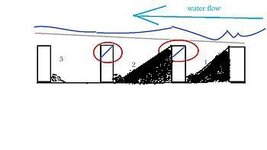

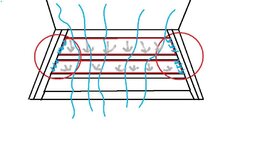

This idea is similar in concept to to the New Zealand Hydraulic riffles, however instead of supplying the water from above like on those, I use the sides. 6 water holes per chamber, 3 on each side about 1/8 inch in diameter each. The first two chambers have a 45 degree back slope which serves two purposes. First, it lessens the material buildup in the riffle by keeping it shallower (and thus easier to keep fluidized), and second it allows the heavies to sink into the deeper part of the chambers. Most of the gold will not make it past the first chamber, but if it does, with this design it has 2 more chambers to settle in.

The purpose of the double flare is to speed up the material at first to push the lighter tailings out, then to slow it down again where it widens to drop the fine gold.

I built it to self classifies to about 6 mesh, but I can change it to any size by switching grizzly if needed. The exit port for tailings under the grizzly is 1/2 inch high.

I tested it a couple times now, but only took video the one time, and so far it seems to work great, catching down to sub 100 mesh easily. More tests and video showing it in action coming soon.

Upvote

0

we promise not to disclose where we see this at.............

we promise not to disclose where we see this at.............