hunter_46356

Hero Member

- Feb 12, 2012

- 502

- 306

- Detector(s) used

- NOx 800, AT Pro

- Primary Interest:

- All Treasure Hunting

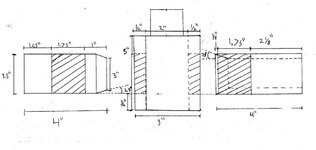

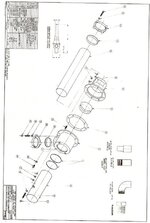

I have done alot of research and reading (as much as I could find) on the internet about "couple" or "infinity" jets for dredging. Not really alot out there. Everything I've read says this is the way to go.... as they seem to be 2 to 3 times more efficient than power jets or a suction nozzle. I'm sceptical because if this is the case why isn't there more information about them or diy and home build info out there? Is there any one here that has successfully built one of these themselves? Is it worth the time and trouble. If you have tried what... worked or what didn't? I'm working with a 2.5hp 2" pump and would like to put together a dredge for processing material into a highbanker for now and later a possible floating dredge. I know my pump is not "all that" for a dredge build and thats why I want to get all the performance I can out of it. The pic I've attached is the best image I've found. I've also found conflicting differences in optimum degree of angle and gap within the mixing chamber. Some say angle should be 11* not 23* as in the pic. This may have something to do with the dia. of the pipe used. I've found recommended gap sizes from 1/16th" to 1/4" + but this can be adj. if the jet is built to thread in and out with lock nuts to keep things in place when best performace is reached. Good Guy this has got to tweek your McGyver mind. What do ya think?