- Jun 3, 2007

- 1,207

- 2,046

- Detector(s) used

- A sharp eye, an AquaPulse and a finely tuned shrimp fork.

- Primary Interest:

- Shipwrecks

Since this forum seems to be in the doldrums here is a thought I've had while landlocked...

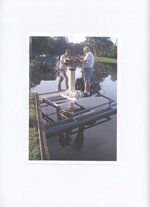

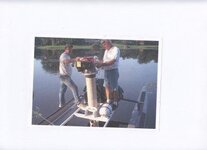

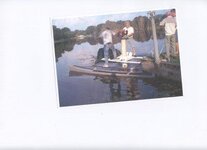

Has anyone tried a pontoon boat/barge with a midships located diesel engine running into a blower setup? Big old pontoons in need of deck repair can often be had for a very reasonable price. A Cummins truck engine ($750 at the U-Pull salvage yard), a right angle drive, a prop, some well thought out bracing and downward ducting...

Reasons in favor:

The 90 degree turn in stern mounted mailboxes comes with a significant cost in efficiency.

Much easier to maintain a deck mounted engine than one mounted below-decks.

Less wear and tear on the propulsion units on your boat.

If the blower motor quits, you can still get home with the towboat/tender.

Fuel costs. Fuel costs. Fuel costs.

Been done? Won't work? My brain is suffering from too much time out of seawater?

Has anyone tried a pontoon boat/barge with a midships located diesel engine running into a blower setup? Big old pontoons in need of deck repair can often be had for a very reasonable price. A Cummins truck engine ($750 at the U-Pull salvage yard), a right angle drive, a prop, some well thought out bracing and downward ducting...

Reasons in favor:

The 90 degree turn in stern mounted mailboxes comes with a significant cost in efficiency.

Much easier to maintain a deck mounted engine than one mounted below-decks.

Less wear and tear on the propulsion units on your boat.

If the blower motor quits, you can still get home with the towboat/tender.

Fuel costs. Fuel costs. Fuel costs.

Been done? Won't work? My brain is suffering from too much time out of seawater?