Sluicedog

Jr. Member

- Jul 5, 2007

- 78

- 45

- Detector(s) used

- Whites GMT, Garrett Gold Stinger, Garrett XL500 Pulse, 2" Sub-Dredge,Goldsnare SGS-1, ELF detector, MFD w/electronic detector

- Primary Interest:

- Prospecting

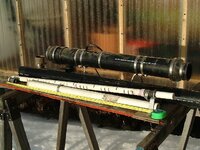

Does anyone know how this air dry washer works, inside details... check out the movie, or have experience with it in a gold bearing area?

It seems some cyclonic action is inside, maybe this separates the heavies.

It seems some cyclonic action is inside, maybe this separates the heavies.