TerryC

Gold Member

- Jun 26, 2008

- 7,797

- 11,180

- Detector(s) used

- Ace 250 (2), Ace 300, Gold Bug 2, Tesoro Cortes, Garrett Sea Hunter, Whites TDI SL SE, Fisher Impulse 8, Minelab Monster 1000, Minelab CTX3030, Falcon MD20, Garrett Pro-pointer, Calvin Bunker digger.

- Primary Interest:

- Metal Detecting

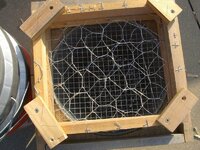

I recently viewed a video that showed a good way to classify loose dirt. The video showed two 5 gallon buckets, one inside the other. The inside bucket had numerous holes drilled in the bottom. The idea is to use a shovel to add dirt.. in the stream or dry... to the bucket and then aggitate till the small stuff is in the lower bucket. My brother TimC has a BETTER idea! Instead of drilling holes, he "sews" half-inch hardware cloth to the cut-out bottom. More dirt falls to the bottom bucket. More dirt, less time, more color! TTC

Upvote

0

My old homemade classifier wasn't built as nice as yours, thanks for the pic. My new one looks and feels sturdy and ready for action.

My old homemade classifier wasn't built as nice as yours, thanks for the pic. My new one looks and feels sturdy and ready for action.