panningjack

Full Member

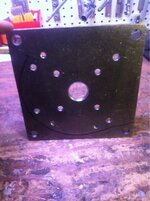

I'm making several changes to the 4". Modifications to the sluice like I mentioned in the reverse 3 stage thread. Mods to my jet to keep it from dragging in shallow water and reduce drag in fast water. And adapting my old gold divers pump to attach to a more efficient motor. I'll post with pics of these changes as I'm working on them and get them completed.