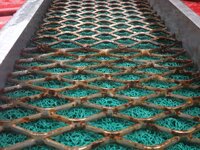

I'm building a 2 inch dredge and the build is going great, only thing is.... Something just doesn't seem right, I know I don't have riffles out in yet but that's what treasure net I for so here are some pics and will take any advice under consideration. I have sluiced in the past so this isn't new to me but the dredge concept is, same basic ideology just bigger and more complex. As I get farther in the build I'll put more pics up for further aid .... Any suggestions on the expanded metal or riffle design would e helpful that's the main part I'm having trouble designing

Amazon Forum Fav 👍

Attachments

Last edited: