daniel2015

Jr. Member

- Sep 28, 2015

- 31

- 57

- Primary Interest:

- All Treasure Hunting

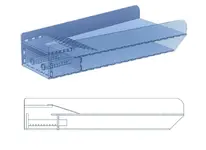

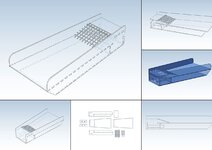

Since tax, customs and shipping to europe is ridiculously expensive I've made a simple design based on the Bazooka Mini Trap Sluice. Everyone with access to a small table top CNC or Laser Cutter could make it. Had to guess the dimensions based on pics and some info from various forums. Here's the preview for the Mini. Would love to do that for the bazooka prospector to build my own but need someone who can give me some details, dimensions and pics.

Btw. here is the PDF tutorial and the proper DXF file in case you want to build your own mini fluid bed sluice:

diy_mini_fluid_bed_sluice.pdf

diy_mini_fluid_bed_sluice.dxf

Btw. here is the PDF tutorial and the proper DXF file in case you want to build your own mini fluid bed sluice:

diy_mini_fluid_bed_sluice.pdf

diy_mini_fluid_bed_sluice.dxf

Last edited: