DizzyDigger

Gold Member

- Dec 9, 2012

- 6,475

- 13,187

- Detector(s) used

- Nokta FoRs Gold, a Gold Cube, 2 Keene Sluices and Lord only knows how many pans....not to mention a load of other gear my wife still doesn't know about!

- Primary Interest:

- Prospecting

After using a regular, bucket top sized classifier since I was

young, I broke down last year and built a manual trommel.

The trommel works great for dry material, but without a

spraybar, pump, etc. it's near worthless for classifying

the wet, rocky riverbank gravel.

The bucket top classifiers just wear my ass out, and the

constant up-down, lifting and shaking, etc. throws my

equilibrium way out of whack. They also don't classify

much material at one time.

So, what to do?

Chewed on it for a few days, and came up with an idea of

using a large tub to hold the classified material, and then

use a smaller tub as the classifier.

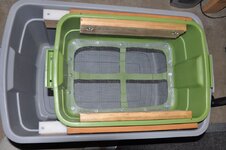

I wanted to make the classifying action (back, forth, etc) as

smooth as possible, so I added strips of cutting board material

(made of poly-something) to the bottom of the classifier

tub runners, and on the top of the rails mounted to the large

tub.

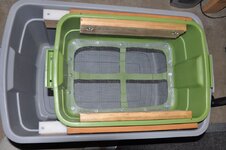

Might be easier to make sense out of in pictures:

The large tub is a 38 gal. Roughneck, and the classifier tub

is a 10 ga. Roughneck. First was cutting the bottom of the

10 gal. tub and installing the 1/8" screen, and then adding

the rails to both tubs. Overall it took about 6 hrs. to complete,

and no doubt some of you could build it much quicker.

Couple more shots:

Tried it out yesterday afternoon by a local creek, and it worked

fantastic! The rails hold all the weight, and the classifier tub slides

back and forth on the hard plastic runners like it's on ice. Took me

only 15 min. to dig and classify about 30 gal. of -1/8" material ...

(p.s. ran it all through the Cube and didn't get squat.. )

)

young, I broke down last year and built a manual trommel.

The trommel works great for dry material, but without a

spraybar, pump, etc. it's near worthless for classifying

the wet, rocky riverbank gravel.

The bucket top classifiers just wear my ass out, and the

constant up-down, lifting and shaking, etc. throws my

equilibrium way out of whack. They also don't classify

much material at one time.

So, what to do?

Chewed on it for a few days, and came up with an idea of

using a large tub to hold the classified material, and then

use a smaller tub as the classifier.

I wanted to make the classifying action (back, forth, etc) as

smooth as possible, so I added strips of cutting board material

(made of poly-something) to the bottom of the classifier

tub runners, and on the top of the rails mounted to the large

tub.

Might be easier to make sense out of in pictures:

The large tub is a 38 gal. Roughneck, and the classifier tub

is a 10 ga. Roughneck. First was cutting the bottom of the

10 gal. tub and installing the 1/8" screen, and then adding

the rails to both tubs. Overall it took about 6 hrs. to complete,

and no doubt some of you could build it much quicker.

Couple more shots:

Tried it out yesterday afternoon by a local creek, and it worked

fantastic! The rails hold all the weight, and the classifier tub slides

back and forth on the hard plastic runners like it's on ice. Took me

only 15 min. to dig and classify about 30 gal. of -1/8" material ...

(p.s. ran it all through the Cube and didn't get squat..

)

)Amazon Forum Fav 👍

Last edited:

Upvote

2