mike(swWash)

Hero Member

- Feb 6, 2008

- 758

- 1,447

- Detector(s) used

- Whites Spectrum XLT with about 1/4" of dust on it and can't even remember how t turn it on?!?!?

- Primary Interest:

- Prospecting

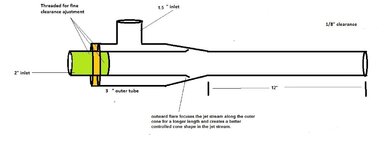

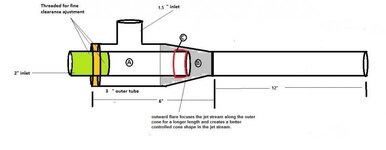

Here's what I have been able to design using the limited info available online.

Please feel free to give feedback about what I got wrong. I'd like to get it as close to right the first time as possible. The only part of the jet I don't have the ability to make myself is the tapered cone on the outlet end, but my local machine shop can. I'll then weld it all together myself.

I know a high pressure pump will create more suction but with the supposed 3x increase in suction over a standard type suction nozzle, I wonder if a much cheaper lower pressure trash pump might work at least as well as a standard nozzle until I acquire a better pump.

Please feel free to give feedback about what I got wrong. I'd like to get it as close to right the first time as possible. The only part of the jet I don't have the ability to make myself is the tapered cone on the outlet end, but my local machine shop can. I'll then weld it all together myself.

I know a high pressure pump will create more suction but with the supposed 3x increase in suction over a standard type suction nozzle, I wonder if a much cheaper lower pressure trash pump might work at least as well as a standard nozzle until I acquire a better pump.

sounds kinds heavy with the batterys. maybe if you had a small generator and made a voltage reducing setup but then your defeating the purpose of backpackable and the non-mechanized areas.

sounds kinds heavy with the batterys. maybe if you had a small generator and made a voltage reducing setup but then your defeating the purpose of backpackable and the non-mechanized areas.